Trusted Die Cast Manufacturer

For nearly 20 years, CCS has been supplying high quality die castings to manufacturers around the world. Our experienced team creates solutions for your exact specifications, from the formative stages of engineering and prototyping through machining, finishing, assembly, packaging and shipping, to meet your production needs.

Consistent affirmation from nearly 80 customers worldwide

CCS Die Casting is your preferred manufacturing partner

CCS is a leading company in the industry, known for providing high quality products and excellent customer service with its many state-of-the-art facilities.

Floor space

A variety of cutting-edge equipment

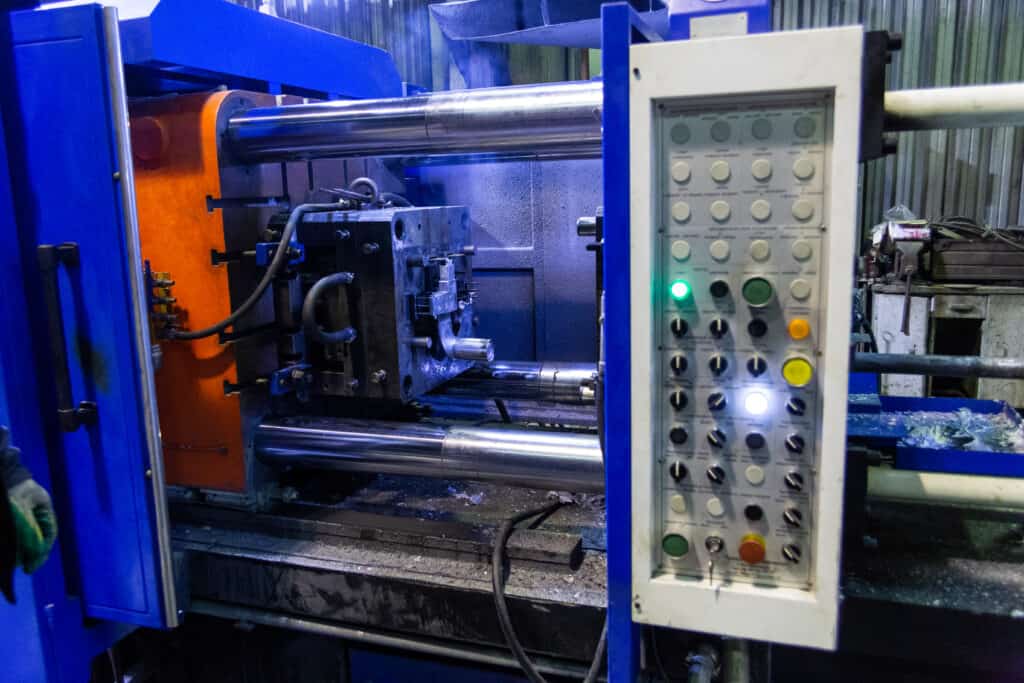

The state-of-the-art facility includes 16 die casting machines, a centralized melting system and separate furnaces, and a variety of other finishing equipment that can support custom projects for a wide range of metals.

Undertake various bulk orders

We offer high, medium and low volume die castings to give our customers more flexible choices.

Your Top One-Stop Die Casting Service Resource

CCS offers comprehensive die casting services, including design and engineering support, installation and maintenance, and training and support.

Die Casting Service

Die casting is at the heart of what CSS does. We design and manufacture custom parts to fit our customers’ specific projects. With our efficient processes, we provide versatile die casting services and quality parts to customers in a wide range of industries.

Machining and Test Assembly

CCS also offers a wide range of machining and finishing services, such as vibratory deburring, shot blasting, plating, and more. In addition, CSS’ extensive assembly and testing capabilities mean that your product is ready to go when it arrives at the dock.

Mold Design and Manufacturing

Our engineers are skilled in providing support, including new mold design and manufacturing, for the smooth transfer of your existing die casting molds.

We proudly serve a variety of industries

At CCS, we are proud to use die casting technology in a wide range of applications, including automotive, medical and lighting, and industrial equipment.

Automotive

Medical

Telecommunications and Lighting

Industrial equipment

Contact the industry's leading die-casting supplier immediately for a free quote

Our Specialties

At CCS, we are able to process a variety of metals, including aluminum, zinc and magnesium, using our state-of-the-art die casting equipment.

Aluminum Die Casting

CCS is a leading provider of aluminum die-casting services for a wide range of industries. Our state-of-the-art facility is equipped with advanced die-casting machines and technology, allowing us to produce high-quality aluminum parts with exceptional precision and accuracy.

But why choose aluminum for your die-casting needs? Here are some of the key advantages of using CCS’s aluminum die-casting service:

- Aluminum is a lightweight metal, making it an excellent choice for parts that need to be portable or easy to handle.

- Aluminum has a high strength-to-weight ratio, so parts made with aluminum can be both lightweight and durable.

- Aluminum has good corrosion resistance, making it suitable for use in a wide range of environments, including outdoor applications.

- Aluminum has excellent thermal and electrical conductivity, making it suitable for a variety of applications, including heat exchangers and electronic components.

- Aluminum is a sustainable and recyclable material, making it an environmentally-friendly choice for many applications.

Zinc Die Casting

CCS is a leading provider of zinc die-casting services for a wide range of industries. Our state-of-the-art facility is equipped with advanced die-casting machines and technology, allowing us to produce high-quality zinc parts with exceptional precision and accuracy.

But why choose zinc for your die-casting needs? Here are some of the key advantages of using CCS’s zinc die-casting service:

- Zinc is a strong and durable metal, making it an excellent choice for parts that need to withstand high levels of stress and wear.

- Zinc has a low melting point, making it easy to cast into complex shapes with fine details.

- Zinc has a relatively low cost compared to other metals, making it an economical choice for many die-casting applications.

- Zinc has good corrosion resistance, so parts made with zinc can have a long service life, even in harsh environments.

- Zinc can be easily plated with other metals, such as nickel or chrome, to improve its appearance and enhance its performance.

Magnesium Die Casting

CCS is a leading provider of magnesium die-casting services for a wide range of industries. Our state-of-the-art facility is equipped with advanced die-casting machines and technology, allowing us to produce high-quality magnesium parts with exceptional precision and accuracy.

But why choose magnesium for your die-casting needs? Here are some of the key advantages of using CCS’s magnesium die-casting service:

- Magnesium is one of the lightest structural metals, making it an excellent choice for parts that need to be lightweight and strong.

- Magnesium has a high strength-to-weight ratio, so parts made with magnesium can be both lightweight and durable.

- Magnesium has good heat and electrical conductivity, making it suitable for a variety of applications, including electronic components and heat exchangers.

- Magnesium can be easily cast into complex shapes, making it a versatile material for a wide range of parts and components.

- Magnesium has a high recycling rate, making it an environmentally-friendly material choice.

Precision Die Casting Services | Since 2005

CCS is a die-casting company that specializes in the production of high-quality die-cast parts for a variety of industries. Founded in 2005, we have been serving the needs of our customers for over 17 years.

Our state-of-the-art facility is equipped with advanced die-casting machines and technology, allowing us to produce parts with exceptional precision and accuracy. We offer a wide range of die-casting services, including aluminum die-casting, zinc die-casting, and magnesium die-casting. Our experienced team of engineers and technicians work closely with our customers to ensure that their specific needs are met and that their parts are produced to the highest quality standards.

In addition to our die-casting capabilities, we also offer a variety of value-added services, such as machining, assembly, and finishing. This allows us to provide our customers with a complete solution for their die-cast parts needs, from design and prototyping to final production.

At CCS, we are committed to providing our customers with the highest level of service and support. We have a reputation for delivering on-time and on-budget, and we pride ourselves on our ability to meet the most demanding deadlines. Whether you need a few prototype parts or a large production run, CCS is the partner you can count on for all of your die-casting needs.

Listen to the voices of our customers

Brandon Johnson

We are very satisfied with the die-cast parts that CCS produced for us. For us in the automotive industry, product quality is the first priority, and they delivered.

Kevin Miller

During these two years of cooperation, CCS has always done an excellent job of fulfilling each of our orders, communicating with us and meeting our needs in a timely manner at every stage of production, which has earned CCS our trust.

James Davis

I am very satisfied with CCS's service, they have perfectly fulfilled my demanding requirements in terms of delivery time and quality, they are a truly responsible company and I am glad I chose CCS!

Quick answers to your concerns and questions

We will provide you with answers to common questions and concerns encountered by the industry and other customers.

Yes, CCS can use molds from other casting companies; however, we must evaluate the quality of the tooling before putting it into production to ensure that we get the best quality parts.

To expedite your request for quotation, we recommend that you sign our NDA form. We can use your form if necessary, but be aware that this may slow down the RFQ process.

- CCS offers zinc, aluminum and magnesium die-cast alloys.

The minimum or maximum cross-sectional wall thickness of any part depends heavily on the overall part size and design. For example, a wall thickness of 0.010″ is possible if it is partial, but not if it spans the entire length of a 4″ long part.

Typically, the optimum wall thickness is 0.040″ to 0.120″ and is related to the overall size of the part. Minimizing the wall thickness also reduces the material content of the part and its cost.

We have virtually every surface treatment available for aluminum die casting, including all plating, painting, e-coating, anodizing, and chemical films.

Yes, we can anodize die-cast aluminum. For larger parts, it is a functional coating that can be used as a primer for painting or to provide additional corrosion resistance. For smaller parts that “fit in the palm of your hand”, it can be decorated with the proper tooling design and production process.