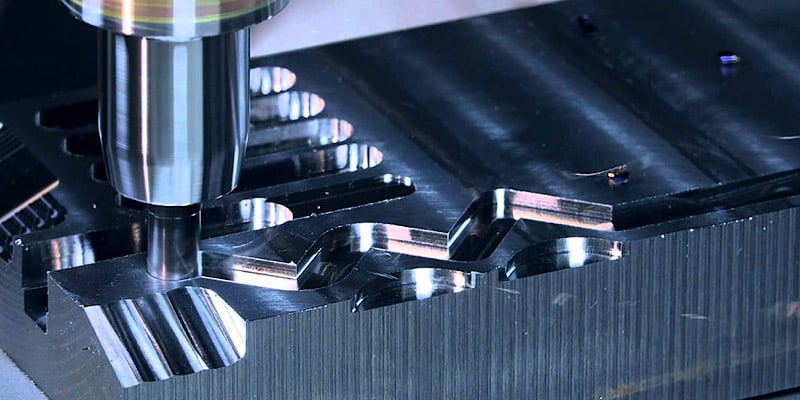

We provide professional casting services and also provide you with supporting CNC machining services.

The two main CNC machining processes we offer are CNC turning and CNC milling. Other machining processes include drilling.

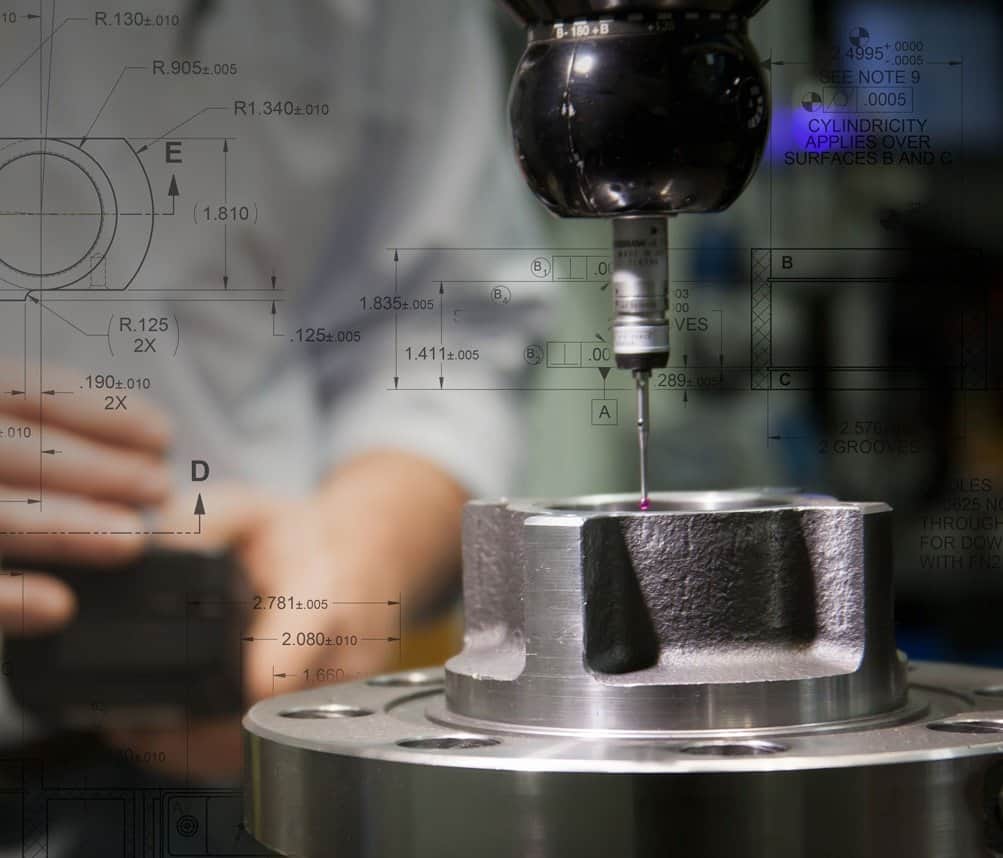

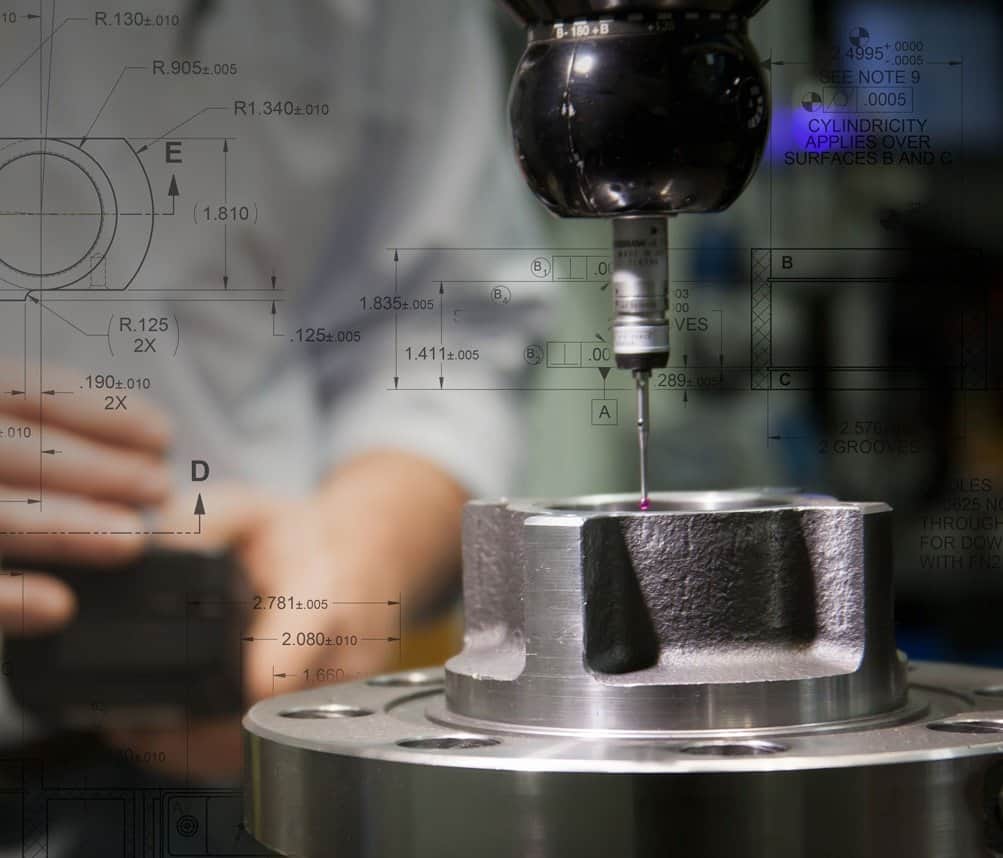

The most important aspect of ensuring the reliability of cast parts is a casting quality verification process that is both meticulous and detail-oriented.

When rigorous and comprehensive metal casting inspection methods are combined with improved metal casting quality standards, parts are produced with improved quality and performance.

At CCS, we use world class casting inspection methods to manufacture high performance parts.

The rapid tooling allows you to use actual production grades of material, giving you a clearer picture of how the part will function in real-world applications and enabling you to test and confirm that you have made the right material choice.

Parts are also injection molded just like they are in production, so you can also use them for stress and impact testing, for example, to explore any weak areas due to fusion lines or other defects in the injection molding process, such as shrinkage and warpage.

With this information, you can better determine if any changes need to be made before expensive production tooling.

We take pride in our excellent work. Many of our satisfied customers take the time to write about their experience with CCS. This is what they had to say.

I was very excited to work with CCS, who solved my problems in choosing raw materials and processes, and developed the most suitable solution for me in terms of price. CCS communicated with me fully in every aspect of the work, which confirmed my choice and I look forward to a longer-term cooperation in the future.