CCS provides reliable casting solutions to the automotive industry. With state-of-the-art technology and skilled professionals, we deliver high-quality parts on time and within budget. Trust CCS for your casting needs.

CCS can produce castings with internal or external features, thin walls and internal channels to achieve near-net shapes, which can reduce material waste and machining costs.

CCS can offer a variety of metal alloys and casting methods to suit different applications and specifications, enhancing performance and durability of automotive parts.

CCS offers full service, custom casting solutions. We will customize auto parts to meet your specific needs and provide one-stop custom auto parts solutions.

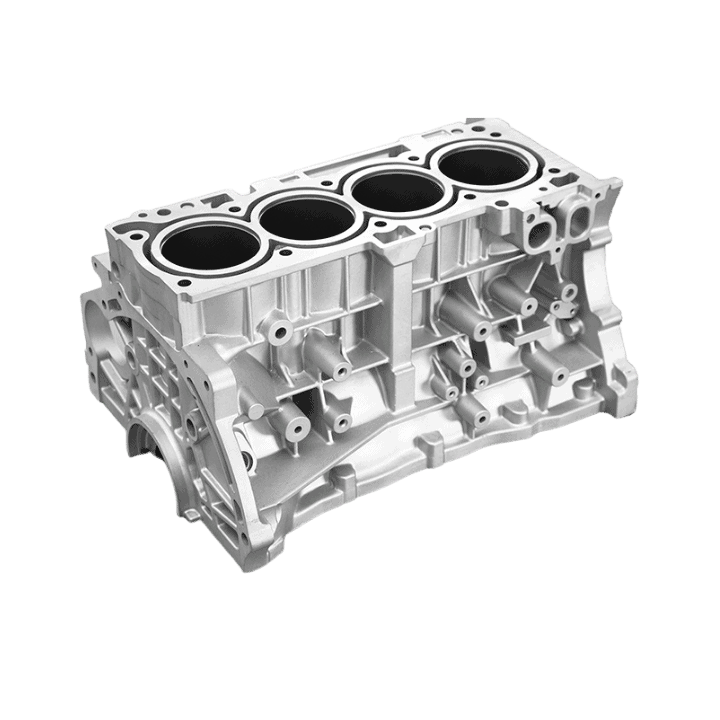

CCS, as a casting service provider in the automotive sector, is able to produce a variety of parts such as engine assemblies, cylinder heads, transmission housings, suspension components, brake system components, steering system components, and other precision-cast parts used in automotive applications.

Reasons why casting is used in the automotive field

Casting allows for the mass production of complex parts at a lower cost compared to other manufacturing processes like machining or forging.

Casting can produce lightweight parts with thin walls and complex shapes that are difficult to achieve with other methods. This can help automakers meet fuel efficiency and emission standards.

Casting can take advantage pf a variety of materials, including aluminum, magnesium, and various alloys, allowing automakers to choose the material that best meets their requirements for strength, durability, and weight.

Casting allows for the production of parts with complex geometries, including internal features and undercuts that other methods cannot achieve.

Here is our summary of materials commonly used for casting in the automotive field.

This lightweight and corrosion-resistant material is commonly used for engine blocks, cylinder heads, transmission cases, and other components in modern vehicles.

Magnesium is even lighter than aluminum, making it an attractive option for weight reduction in certain applications, such as transmission cases.

Zinc is commonly used for die-casting parts such as handles, brackets, and other small components.

Due to its excellent strength-to-weight ratio, high-strength steel is used for various components, including suspension parts and steering components.

This process uses sand molds to form metal parts. Sand casting can produce complex shapes and large parts with low cost. However, sand casting has low dimensional accuracy and surface finish. Some examples of automotive parts made by sand casting are engine blocks, cylinder heads and intake manifold.

It uses metal molds to form metal parts. Gravity die casting has higher dimensional accuracy and surface finish than sand casting, but lower than pressure die casting. Gravity die casting can produce medium-sized parts with moderate complexity. Some examples of automotive parts made by gravity die casting are engine blocks, cylinder heads and intake manifold.

This process takes advantage of high pressure to inject molten metal into molds. Pressure die casting has high dimensional accuracy and surface finish, but also has high cost and limited complexity. It can produce small-sized parts with thin walls. Some examples of automotive parts made by pressure die casting are pistons, piston rings, cylinder liners and cylinder blocks.

Investment casting uses wax patterns to form ceramic molds that are then filled with molten metal. It not only has very high dimensional accuracy and surface finish, but also has high cost and limited size. Intricate shapes and fine details can be produced via investment casting. Some examples of automotive parts made by investment casting are valves, turbocharger wheels, fuel injectors and gears.

what makes us different

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.

our services

join the success

We take pride in our excellent work. Many of our satisfied customers take the time to write about their experience with CCS. This is what they had to say.

I was very excited to work with CCS, who solved my problems in choosing raw materials and processes, and developed the most suitable solution for me in terms of price. CCS communicated with me fully in every aspect of the work, which confirmed my choice and I look forward to a longer-term cooperation in the future.