CCS, a leading metal casting service provider that offers a range of manufacturing solutions. Whether you need die casting, investment casting, sand casting, or machining, CCS has the expertise and facilities to deliver high-quality products on time and on budget.

Custom Metal Casting Service

CCS is your trusted partner for all your metal casting requirements. A variety of casting and machining services are provided to meet your needs in CCS.

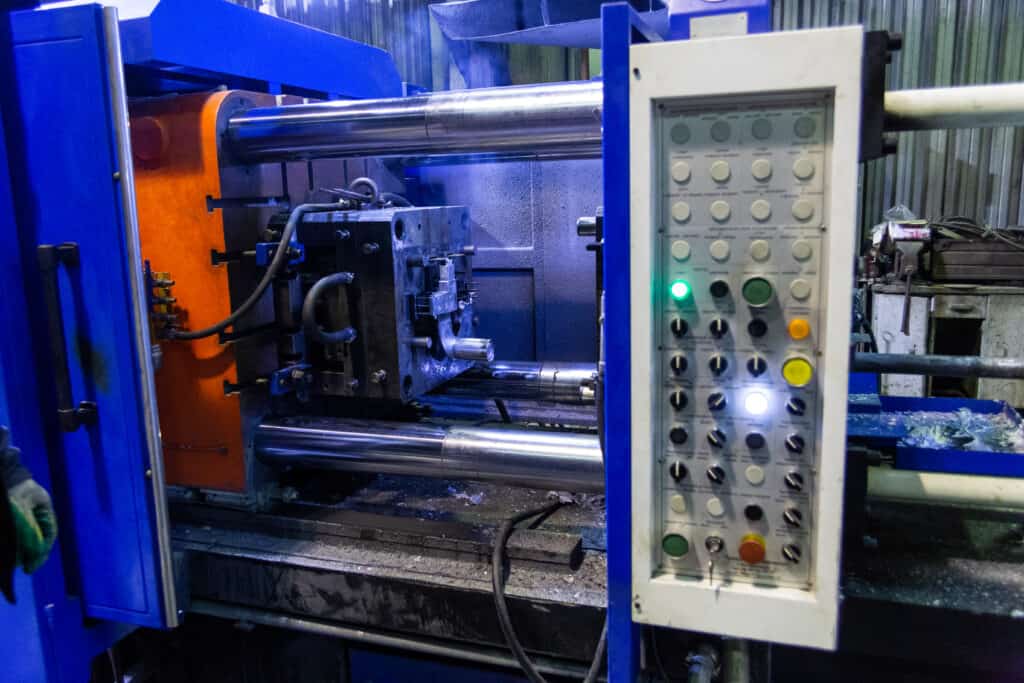

CCS has the edge of having an integrated manufacturing campus that allows for efficient coordination and prompt production. Cutting-edge equipment and processes ensure castings’ accuracy, durability, efficiency, and sustainability.

With nearly 20 years of casting experience, CCS can handle any challenge and provide you with the best results. Contact CCS today and get a free quote for your project!

This process involves placing a pattern of the desired part in a wooden or metal frame called a flask. Sand is then packed around the pattern to form a mold cavity. The pattern is then removed and molten metal is poured into the mold. After cooling, the sand mold is broken and removed to reveal the casting.

This process involves creating a wax pattern of the desired part and coating it with ceramic slurry. The coated pattern is then heated to melt out the wax and form a ceramic mold. Molten metal is then poured into the mold and solidified. The ceramic mold is then broken and removed to reveal the casting.

This process uses a metal mold called a die that consists of two clamped halves. Molten metal is injected into the die cavity under high pressure and speed. The metal solidifies quickly and the die halves are opened to eject the casting.

CCS is a custom metal casting service provider that providing a wide range of metal raw materials for different industries and applications.

such as A356, A380, A413, etc. These alloys are lightweight, corrosion-resistant and have good mechanical properties. Aluminum Alloy castings are suitable for aerospace, automotive and other applications that require high strength-to-weight ratio.

such as ZA-8, ZA-12, ZA-27, etc. These alloys have high hardness, wear resistance and dimensional stability. They are ideal for electrical components, housings and connectors that require precision and durability.

like AZ91D, AM60B, AM50A, etc. These alloys are the lightest among common metals and have excellent thermal conductivity and shock absorption. They are used for automotive parts, electronic devices and medical equipment that need to reduce weight and improve performance.

such as C86500, C87600, C87800, etc. These alloys have high electrical conductivity, thermal conductivity and corrosion resistance. They are widely used for electrical contacts, switches and terminals that need to withstand high temperatures and currents.

such as ductile iron (ASTM A536), gray iron (ASTM A48), malleable iron (ASTM A47), etc. These alloys have high strength, toughness and machinability. They are commonly used for engine blocks, pump housings and valves that need to resist wear and vibration.

At CCS, we understand that every customer has unique needs and requirements when it comes to metal casting. That’s why we work closely with our customers to develop a customized service process that meets their specific needs.

CCS works with our customers to understand their design and engineering requirements, providing support to their casting design and making sure the castings are in good performance.

CCS uses state-of-the-art technology to create precise tooling and prototyping that meet the customer’s exact specifications. Our experienced team ensures the tooling is designed for efficiency, accuracy, and durability.

Once the tooling and prototyping are complete, we begin the casting production process using high-quality materials and advanced casting techniques. Our team of skilled technicians and engineers keeps each casting meeting customer’s specifications for quality, precision, and performance.

Once the part has solidified, it is removed from the mold and any excess material is removed through processes such as grinding, sandblasting, or machining. Additional finishing processes such as polishing or painting may also be applied.

The final step in the casting service process is inspection to ensure that the part meets the required specifications and quality standards. This may involve non-destructive testing, visual inspection, or other methods to verify that the part is free from defects and meets the required tolerances and surface finish.

Once the parts pass inspection, they are packaged and delivered to the client. Our company can also provide additional services, such as assembly, packaging, and shipping to the client’s end destination.

At CCS, we understand that every customer has unique needs and requirements when it comes to metal casting. That’s why we work closely with our customers to develop a customized service process that meets their specific needs.

Metal casting can produce parts with complex shapes and internal cavities that are difficult or impossible to achieve by other methods.

Metal casting can use a wide range of materials, such as iron, steel, aluminum, brass, bronze, etc., and can also utilize low-cost scrap metal and waste materials.

Metal casting can produce parts with large sizes and weights that are beyond the capacity of other processes.

Metal casting can achieve detailed designs and fine surface finishes that enhance the appearance and performance of the parts.

Metal casting can be economical for small production quantities as well as mass production, as it requires relatively low equipment and labor costs.

Casting can produce parts with minimal waste, making it an environmentally friendly manufacturing method.

If you are looking for a reliable and professional metal casting service provider, CCS will be a good choice.

We have over 20 years of experience in the metal casting industry and have served hundreds of satisfied customers from various fields.

We deliver your parts or assemblies on time and provide after-sales service and technical support for any issues or questions you may have.

We offer customized casting products in a wide range of materials, including butnot limited to aluminum, stainless steel, brass and bronze. We can handle any size and complexity of your project with our advanced equipment and technology.

We adhere to strict quality testing standards and have a professional quality testing team that ensures every part and assembly we manufacture meets or exceed your. We use an X-ray fluorescence (XRF) analyzer (spectrometer) to test the chemical composition of each batch of molten metal before pouring it into the mold.

We take pride in our excellent work. Many of our satisfied customers take the time to write about their experience with CCS. This is what they had to say.

I was very excited to work with CCS, who solved my problems in choosing raw materials and processes, and developed the most suitable solution for me in terms of price. CCS communicated with me fully in every aspect of the work, which confirmed my choice and I look forward to a longer-term cooperation in the future.