Experience the future of aerospace manufacturing with CCS Aerospace. Our revolutionary precision casting solutions set new industry benchmarks, offering lightweight, high-performance components that drive the aerospace industry forward.

We utilize state-of-the-art casting techniques and equipment to ensure the highest level of precision and quality in every aerospace component we manufacture.

Our expert team collaborates closely with clients to optimize designs for casting, leveraging our extensive knowledge and experience in aerospace casting to maximize performance and efficiency.

We adhere to stringent quality control measures throughout the casting process, employing advanced non-destructive testing (NDT) techniques to verify the integrity and reliability of our aerospace parts.

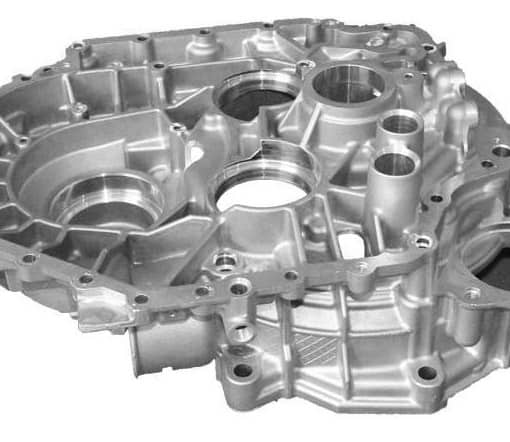

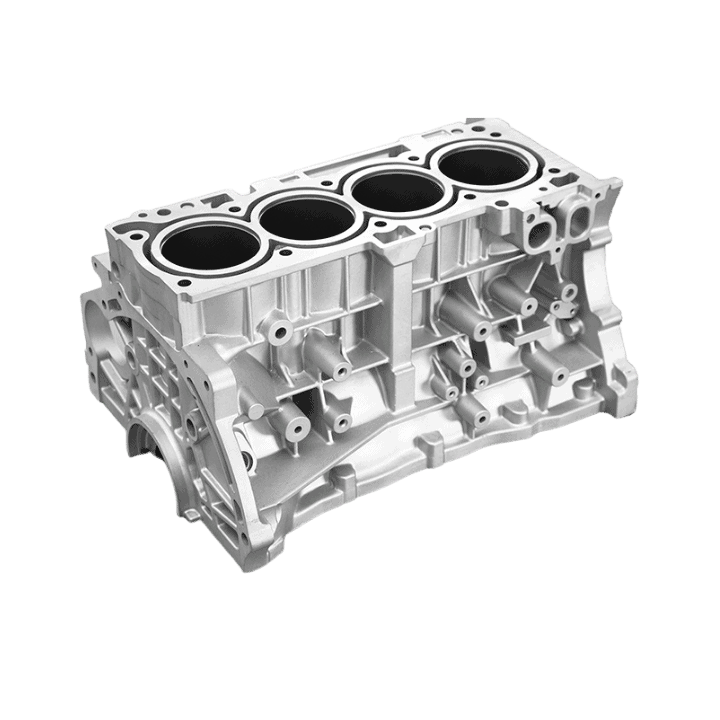

At CCS Aerospace, we specialize in the production of a wide range of critical aerospace components.

Reasons why casting is used in the aerospace field

Casting techniques allow for the production of intricate, complex, and optimized designs that meet the stringent requirements of modern aerospace engineering.

Cast components offer an excellent strength-to-weight ratio, enabling the creation of lightweight structures, leading to reduced fuel consumption and increased efficiency.

Casting minimizes material waste during the manufacturing process, resulting in cost savings, especially when producing complex or large-scale aerospace components.

Casting processes, such as investment casting and precision sand casting, streamline production and reduce lead times, allowing for faster delivery of critical aerospace parts.

Here is our summary of materials commonly used for casting in the aerospace field.

Lightweight and corrosion-resistant, commonly used for non-structural components.

Known for their exceptional strength, high-temperature resistance, and low density, often used in critical engine and structural applications.

Offering a balance of strength, corrosion resistance, and affordability, used in various aerospace applications.

Lightweight and highly machinable, employed in aircraft structures and other non-critical components.

Ideal for complex and high-precision components, investment casting offers tight tolerances and excellent surface finish.

Used for larger aerospace parts, precision sand casting provides cost-effective production with good dimensional accuracy.

Commonly employed for mass production of smaller, intricately detailed aerospace parts, die casting offers high repeatability.

Suitable for high-volume production of parts with consistent quality, permanent mold casting delivers efficient and reliable results.

what makes us different

Our expert team collaborates closely with clients to optimize designs for casting, ensuring manufacturability and optimal performance.

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.

Our modern facilities are equipped with advanced casting equipment, enabling us to deliver precise and high-quality aerospace components.

We provide precision machining and finishing services to ensure the final components meet exact specifications and surface finish requirements.

We employ rigorous quality control measures, including NDT techniques, to verify the integrity and reliability of our cast aerospace parts.

We foster strong relationships with leading aerospace companies, working together to develop innovative casting solutions and ensure customer satisfaction.

Why Choose Us

join the success

Contact CCS Aerospace today to discuss your aerospace casting requirements and experience our commitment to precision, innovation, and reliable service.

We take pride in our excellent work. Many of our satisfied customers take the time to write about their experience with CCS. This is what they had to say.

I was very excited to work with CCS, who solved my problems in choosing raw materials and processes, and developed the most suitable solution for me in terms of price. CCS communicated with me fully in every aspect of the work, which confirmed my choice and I look forward to a longer-term cooperation in the future.