Experience the power of CCS Energy’s precision casting solutions, driving innovation and reliability in the energy sector. Join us in shaping the future of energy production and distribution.

We employ state-of-the-art casting techniques and equipment, ensuring the highest level of precision and quality in energy component manufacturing.

Our experienced team collaborates closely with clients to optimize energy component designs, maximizing performance, and energy efficiency.

We adhere to stringent quality control measures throughout the casting process, utilizing advanced non-destructive testing (NDT) techniques to verify the integrity and reliability of our energy parts.

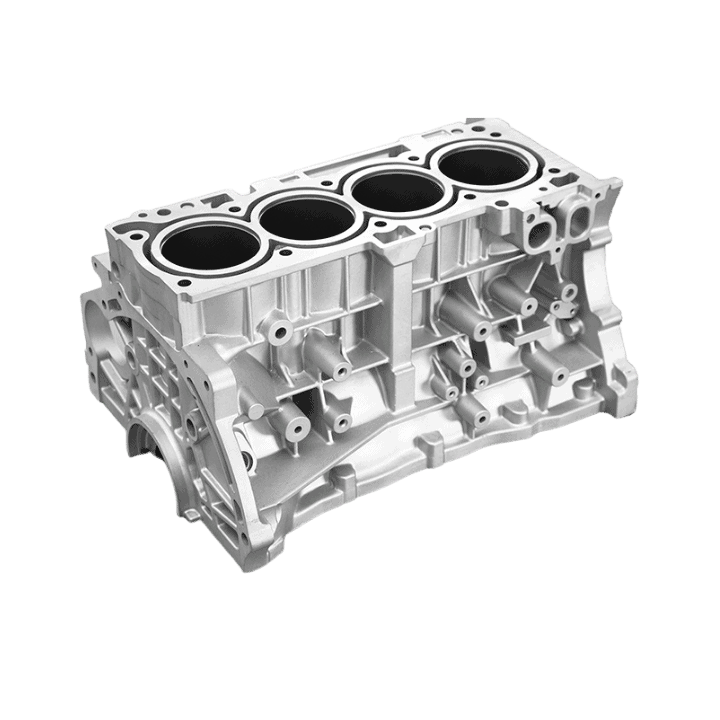

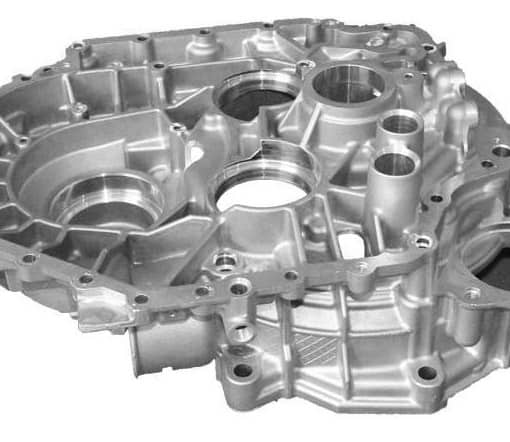

At CCS Energy, we specialize in manufacturing a wide range of energy parts.

Reasons why casting is used in the Energy field

Casting enables the efficient use of materials, reducing waste and environmental impact in energy component production.

Casting offers flexibility in design and adaptability to meet specific requirements of diverse energy systems, providing tailored solutions.

Cast energy components deliver superior strength, precision, and reliability, ensuring optimal energy conversion and long-term operation.

Casting provides cost advantages over alternative manufacturing methods, especially when producing large-scale or custom energy components.

Here is our summary of materials commonly used for casting in the energy field.

Offering high strength, durability, and heat resistance, steel alloys are commonly used in energy applications such as turbine components and infrastructure.

Lightweight and corrosion-resistant, aluminum alloys find applications in renewable energy systems and heat exchangers.

Combining high strength and corrosion resistance, titanium alloys are used in critical components of aerospace, nuclear, and high-performance energy systems.

With excellent electrical conductivity, copper alloys are utilized in electrical power transmission and distribution components.

Ideal for complex and high-precision components, investment casting offers tight tolerances and excellent surface finish.

Suitable for larger energy parts, sand casting provides cost-effective production with good dimensional accuracy.

Commonly employed for mass production of smaller, intricately detailed energy parts, die casting offers high repeatability.

Suitable for the production of hollow cylindrical energy components, such as turbine blades and rocket nozzles.

what makes us different

Our expert team collaborates closely with clients to optimize designs for casting, ensuring manufacturability and optimal performance.

We offer rapid prototyping services for quick validation of energy part designs, as well as efficient tooling development for casting production.

Our modern facilities are equipped with advanced casting equipment, enabling us to deliver precise and high-quality energy components.

We provide precision machining and finishing services to ensure the final components meet exact specifications and surface finish requirements.

We employ rigorous quality control measures, including NDT techniques, to verify the integrity and reliability of our cast energy components.

Our dedicated project management team oversees every stage of the manufacturing process, ensuring efficient communication, on-time delivery, and successful project outcomes.

Why Choose Us

Contact Us Today

Contact CCS Energy today to discuss your energy casting requirements and experience the power of precision, innovation, and reliable service in energy component manufacturing.

We take pride in our excellent work. Many of our satisfied customers take the time to write about their experience with CCS. This is what they had to say.

I was very excited to work with CCS, who solved my problems in choosing raw materials and processes, and developed the most suitable solution for me in terms of price. CCS communicated with me fully in every aspect of the work, which confirmed my choice and I look forward to a longer-term cooperation in the future.