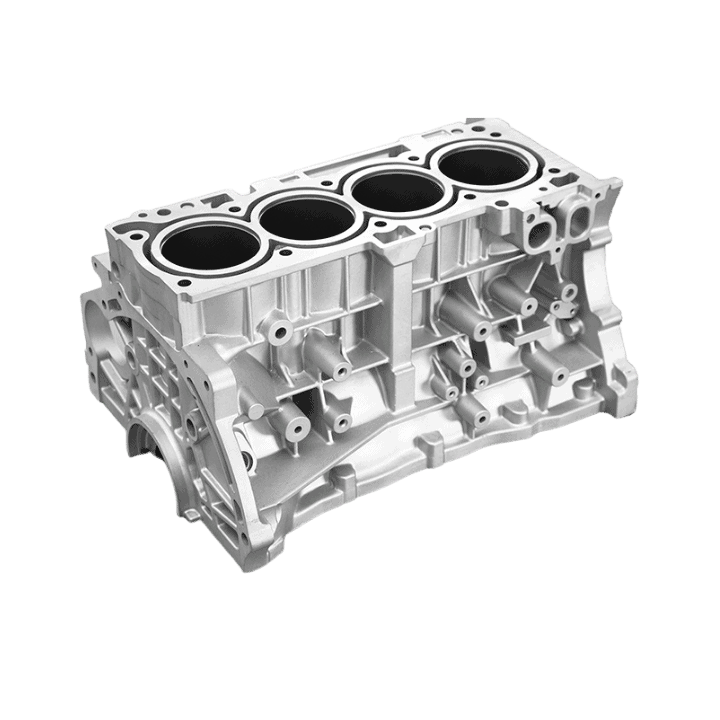

Seeking high-quality, cost-effective, and fast CNC machining? Choose CCS, the leading provider of custom CNC parts for all industries. Get a free quote today!

CCS offers precise parts processing services, delivering high-quality results with advanced CNC machining technology.

CCS is committed to providing high-precision CNC machining services to our customers. Our advanced machining technology and equipment allow us to achieve a high degree of accuracy and precision in our work.

5-Axis Milling

Metals, Plastics

As Fast As One Day

Benefits of Working with CCS

CCS utilizes advanced CNC machining technology to ensure precise and accurate results, meeting tight tolerances and specifications.

CCS can work with a wide range of materials and accommodate various part complexities, providing flexibility for diverse project requirements.

CCS implements rigorous quality control measures to ensure the highest standards of quality, resulting in superior finished parts and components.

By leveraging advanced CNC technology and efficient processes, CCS offers competitive pricing without compromising on quality.

CCS supports customization and prototyping needs, allowing for the creation of unique and innovative designs before proceeding with full-scale production.

CCS values punctuality and strives to meet delivery deadlines, ensuring that your projects stay on schedule.

Reach out to CCS, providing project details and requirements.

Receive a comprehensive quotation with cost estimates, project timeline, and relevant details.

Confirm the order by signing a contract or providing a purchase order, agreeing to the terms and conditions.

Engage in detailed discussions to clarify project needs, feasibility, and complexity.

Optimize the design for production processing by reviewing existing documentation or providing design assistance.

CCS performs production manufacturing processing of parts, performs quality control checks on parts, and arranges for timely delivery or shipment.

Choosing CCS, you can benefit from their expertise, advanced technology, commitment to quality, customization options, timely delivery.

CCS places a strong emphasis on customer satisfaction. They provide responsive communication, attentive support, and proactive collaboration throughout the entire process. You can expect open dialogue, regular updates, and a commitment to meeting your expectations.

CCS can work with a wide range of materials and accommodate diverse industries such as aerospace, automotive, electronics, medical, and more. Their versatility makes them suitable for various project requirements.

CCS invests in state-of-the-art manufacturing and processing equipment, tools and software to ensure efficient and accurate processes. Their commitment to utilizing advanced technology allows them to achieve superior accuracy and consistency in their work.

CCS supports customization and prototyping needs. Whether you require a unique design or a small batch of prototypes before full-scale production, they can work with you to realize your vision.

CCS CNC Machining FAQ

CCS has the capability to work with a wide range of materials, including metals (such as aluminum, steel, brass, and titanium), plastics, wood, and composites.

The turnaround time can vary depending on factors such as project complexity, quantity, and material availability. CCS strives to provide timely delivery and will provide an estimated timeframe based on your specific project requirements.

CCS utilizes advanced CNC machining technology to achieve high precision and accuracy. They have strict quality control measures in place to ensure that the machined parts meet the required specifications and tolerances.

Yes, CCS offers customization options to meet specific design and specification requirements. They work closely with customers to understand their needs and provide tailored solutions.

CCS has a rigorous quality control process, including dimensional inspections, surface finish checks, and other tests to ensure the quality and accuracy of the machined parts.

Yes, CCS has the flexibility to handle both small and large production runs. They can accommodate varying quantities based on your specific project requirements.

We take pride in our excellent work. Many of our satisfied customers take the time to write about their experience with CCS. This is what they had to say.

I was very excited to work with CCS, who solved my problems in choosing raw materials and processes, and developed the most suitable solution for me in terms of price. CCS communicated with me fully in every aspect of the work, which confirmed my choice and I look forward to a longer-term cooperation in the future.