At CCS, we offer the following metal casting quality inspection methods to ensure that every part and assembly we manufacture meets our high level of expectations and that our customers receive the best castings and assemblies in the industry.

Our casting quality control specialists use visual technology to ensure that parts are properly filled with metal (no cracks, tears, holes or voids, unfilled, etc.).

They also meticulously inspect each part to ensure that there is no distortion or bending before continuing with the casting quality process.

In the final stage of inspection, parts are examined and compared to the casting quality control plan and written process instructions.

Finally, the casting quality results are recorded and stored for future use by production department employees and process engineers.

To confirm the correct properties of the metal casting, mechanical tests are performed to confirm the metal of the casting. The test confirms that the properties meet the specified mechanical requirements.

The following mechanical property test methods are performed to confirm proper casting quality.

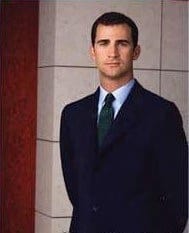

Our experts use the investment casting industry standards as a guide by setting a range of values that casting dimensions can fall into.

During the planning and inspection phase, we also consider the critical part dimensions provided to us by the customer. We then use micrometers, thread and plug gauges, CMM machines, and other approved functional gauges to verify the dimensions of the part.

The accuracy of these measuring tools adds to the dimensional consistency and casting quality of the manufactured parts.

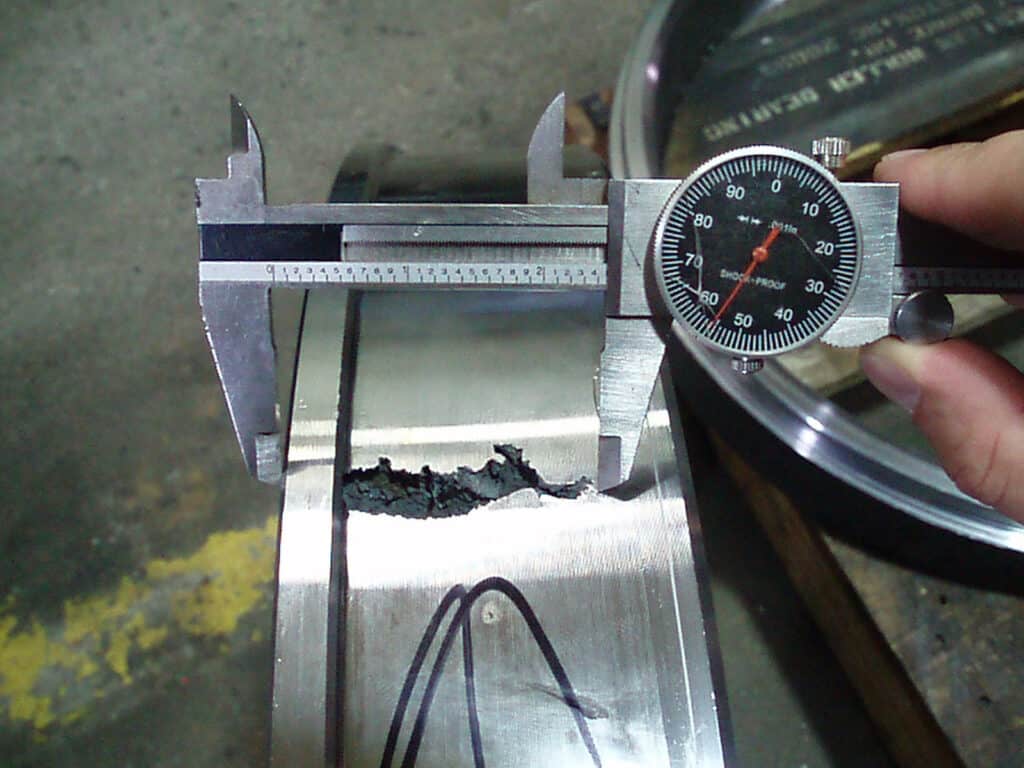

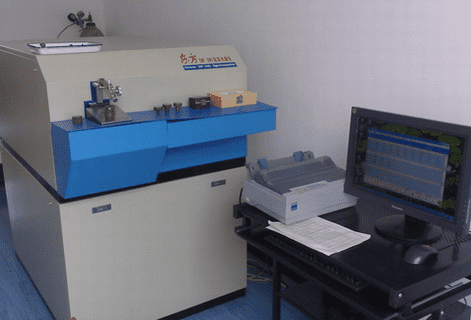

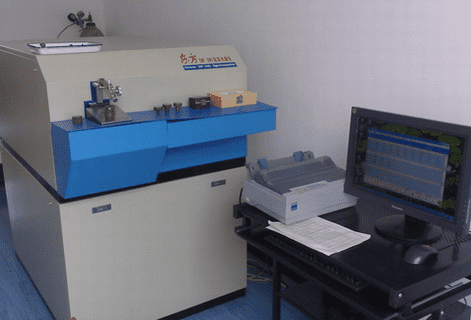

CCS currently uses an X-ray fluorescence (XRF) analyzer [spectrometer] in its metallurgical laboratory. Before pouring the metal from the furnace, a sample of molten metal is poured into a small “test paper” mold and the quality of the casting is evaluated in the spectrometer.

If desired, a small amount of alloying elements can be added to the material to bring the molten alloy to the desired specification. Another specimen is then tested and certified to ensure proper chemical composition.

The chemical composition of each alloy melt is tested and recorded in our database. We then store the records electronically for an indefinite period of time. This testing is performed to ensure that the alloy properties meet the customer’s specifications. Cast alloys are typically specified in accordance with ASTM, AMS and SAE alloy specifications.

CCS performs non-destructive casting quality testing (NDT) on site. This allows us to ensure the quality of our castings without damaging them.

Our in-house NDT facility is staffed with Level II and Level III resident technicians. We are also NADCAP certified for dye (liquid) penetrant testing, magnetic particle testing, and radiographic (x-ray) testing.

Our on-site NDT facility allows CCS to perform a combination of the most common NDT and inspection methods required by many well-known industries, such as aerospace. We use the following types of NDT methods:

We take pride in our excellent work. Many of our satisfied customers take the time to write about their experience with CCS. This is what they had to say.

I was very excited to work with CCS, who solved my problems in choosing raw materials and processes, and developed the most suitable solution for me in terms of price. CCS communicated with me fully in every aspect of the work, which confirmed my choice and I look forward to a longer-term cooperation in the future.