CCS offers premium sand casting services for a wide range of industries. Our experienced professional teams usethe latest techniques and equipment to deliver high-quality products at competitive prices. Trust us for all your sand casting needs!

CCS is a sand casting service company that has been providing customized casting solutions to our customers for nearly 20 years. We have an outstanding reputation for its high-quality products and outstanding customer service.

CCS provides customized sand casting services to meet each customer’s unique needs. We work closely with our clients to understand their requirements and develop sand casting solutions that perfectly fit their specifications. This level of customization help our customers involved in the production and get a prompt feedback.

CCS is equipped with a highly skilled professional team. Our state-of-the-art equipment and technologies help the sand casting processes meet the highest quality standards. The strict quality control processes in CCSS ensure every cast part meets or exceeds customer expectations.

CCS's sand casting services offer excellent value for money, with competitive pricing that allows our clients to achieve significant cost savings. A range of finishing and coating services are provided to help clients receive a fully finished product that is ready for use.

CCS's sand casting services are efficient. Our streamlined production process reduces waste and increases productivity. We use computer-aided design (CAD) software to create detailed 3D models for the client, which allows us to optimize the casting process and reduce lead times.

Die casting is a manufacturing process that can be used to produce parts from a variety of metal alloys.

Aluminum is a lightweight, corrosion-resistant material that is widely used in the automotive, aerospace, and construction industries. Aluminum sand castings are known for their high strength-to-weight ratio and excellent conductivity in thermal and electrical.

Cast iron is a strong and durable material that is commonly used in engine blocks, pump housings, and other industrial components. Iron castings can be made in various grades, each with its unique mechanical properties and heat resistance.

Steel is a versatile and common material in many industries, such as automotive, aerospace, and construction. Various steel grades can be applied to sand casting services due to its unique mechanical properties and corrosion resistance.

Brass is a popular material for decorative castings, such as ornamental gates, lamp posts, and sculptures. It is known for its excellent corrosion resistance, high ductility, and attractive appearance.rass: Brass is a popular material for decorative castings, such as ornamental gates, lamp posts, and sculptures. It is known for its excellent corrosion resistance, high ductility, and attractive appearance.

Bronze is a durable material that is commonly used to produce bearings, gears, and other components that require high wear resistance. Bronze casting get a leg up for their excellent corrosion resistance, thermal conductivity, and attractive appearance.

Sand casting is a versatile casting process that can be applied in various industries. It can be used in automotive, aerospace, construction, industrial equipment and other fields.

Sand casting is widely used in the automotive industry to produce engine blocks, transmission cases, and other automotive components made of aluminum or iron alloys.

The aerospace industry also relies heavily on sand casting to produce complex components made of titanium, aluminum, or other alloys. Sand casting is used to manufacture components such as engine parts, landing gear components, and structural components for aircraft.

Sand casting is applied to the construction industry to produce decorative metal elements such as lamp posts, railing, and ornamental gates. It is also used to produce structural elements such as columns and beams.

Sand casting is widely used in industrial equipment components, such as pump housings, valve bodies, and gearboxes. These components are used in various industries, including oil and gas, mining, and manufacturing.

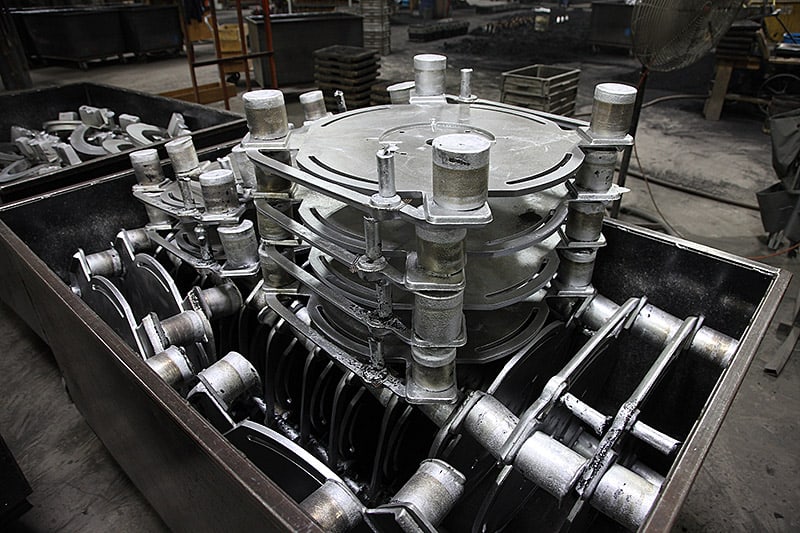

Below are five possible ways to describe the facilities and size of CCS’s sand casting service.

CBS's state-of-the-art facilities allow us to produce high-quality precise casting parts with efficiency. CCS is equipped with advanced casting equipment, specialized tooling and machinery, and a clean and organized work space.

CCS' sand casting is able to produce castings in large quantities. It is ideal for industrial applications requiring large quantities of consistent, reliable parts. CCS uses automation and other production technologies to optimize efficiency and output.

Despite the large scale capabilities, CCS' sand casting services offer a high degree of customization and flexibility. This includes the ability to manufacture castings in a variety of shapes, sizes and materials, as well as providing personalized service and support to meet each customer's unique needs.

Our services have a rigorous quality control process to ensure that each casting part meets the highest standards of quality and reliability. Thorough testing and inspection is performed at every stage of the production process, using advanced tools and techniques to detect any defects or flaws.

Welcome to CCS Die Casting, where we specialize in providing top-quality sand casting services to businesses of all sizes.

CCS's flexibility and ability to customize sand casting solutions can meet a wide range of needs. We are able to produce sand castings in a wide variety of shapes, sizes and materials, providing personalized service and powerful support to our customers.

CCS delivers sand casting solutions on time, meeting the needs of customers with tight production schedules and ensuring parts delivered on time.

CCS is equipped with a highly skilled and experienced expert teams dedicated to providing customers with unique guidance and support throughout the casting process.

CCS is committed to sustainability and environmental responsibility, implementing environmental measures to minimize our impact on the environment.

CCS is a premier sand casting manufacturer, offering a wide range of high quality metal casting services.

Sand casting remains one of the most cost effective and efficient casting solutions, helping to reduce lead times and costs.

Sand casting is cost effective, but may not provide the best solution for every product or part. Key benefits of this casting process include:

Casting metal from sand It is the oldest method of casting metal and one of the most versatile.

One of the most attractive features is that it has the lowest initial set-up costs. The process is also easier to modify and reduces the cost of mold changes.

Because of these features, this casting method is ideal for small to medium production runs, prototype castings, and conversion of welded parts to castings.

We offer a variety of sand casting methods and materials to suit your project, including:

In addition to these processes, we offer complete metallurgical analysis. With our most professional service team, we can prepare metals for analysis to help reduce casting defects and process inefficiencies.

Our solutions also allow for the use of a variety of materials including stainless steel, alloy steel, iron, aluminum, magnesium, brass, bronze and copper.

Our equipment includes magma solidification software to reduce or eliminate porosity. We also utilize coreless induction melting furnaces to increase productivity.

Our casting capabilities range from 1 lb. to 30,000 lbs. per piece. Different materials and methods can be used to achieve the desired results to meet your project needs:

Green Sand Molding

Resin Sand Molding / Shell Molding

No-Bake/Air Set Molding

Complete Metallurgical Analysis

We take pride in our excellent work. Many of our satisfied customers take the time to write about their experience with CCS. This is what they had to say.

I was very excited to work with CCS, who solved my problems in choosing raw materials and processes, and developed the most suitable solution for me in terms of price. CCS communicated with me fully in every aspect of the work, which confirmed my choice and I look forward to a longer-term cooperation in the future.